UART vs SPI vs I2C: Which Protocol Should You Actually Use?

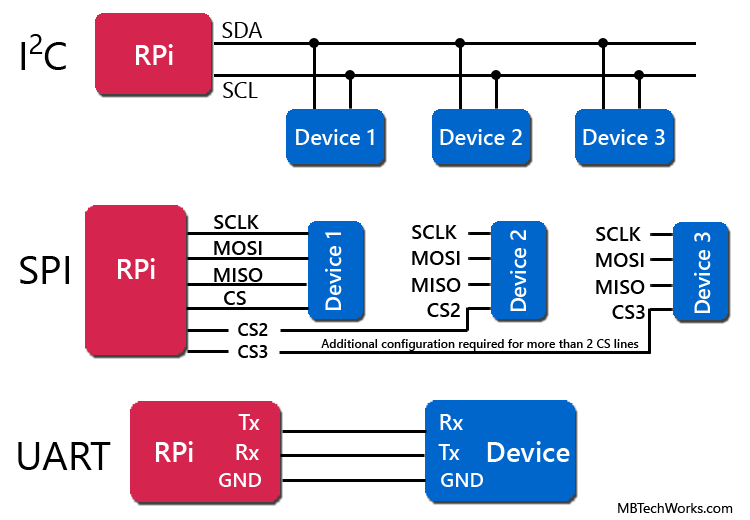

UART / SPI / I²C side‑by‑side wiring overview

If you've ever stared at a microcontroller datasheet wondering whether to use UART, SPI, or I2C for your next project, you're not alone. These three serial communication protocols are the backbone of embedded systems, but choosing the wrong one can lead to headaches down the road.As engineers, we've all been there - debugging a sluggish I2C bus at 3 AM or wondering why our SPI sensor isn't responding. The truth is, each protocol has its sweet spot, and understanding when to use which one can save you countless hours of troubleshooting.The Serial Communication Landscape

Before diving into the comparison, let's understand why serial protocols matter. In embedded development, components need to talk to each other - microcontrollers to sensors, processors to memory, displays to controllers. Serial communication allows this data exchange using fewer wires than parallel interfaces, reducing PCB complexity and cost.Quick Protocol Overview

UART (Universal Asynchronous Receiver-Transmitter)

The Simple One: Point-to-point communicationWires: 2-3 (TX, RX, optional GND)Speed: Typically 9600 to 115200 baud, up to 1 MbpsAddressing: None - direct connection only

SPI (Serial Peripheral Interface)

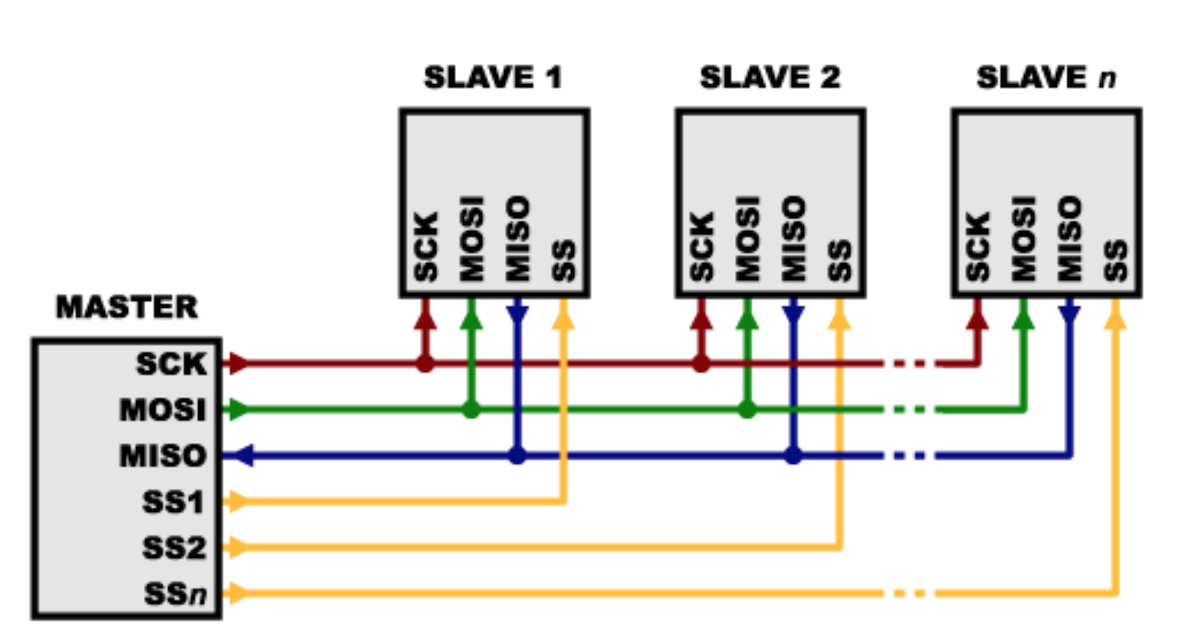

The Speed Demon: High-speed, full-duplex communicationWires: 4+ (MOSI, MISO, SCLK, CS per slave)Speed: 10+ MHz common, can exceed 100 MHzAddressing: Chip select lines for each slave

I2C (Inter-Integrated Circuit)

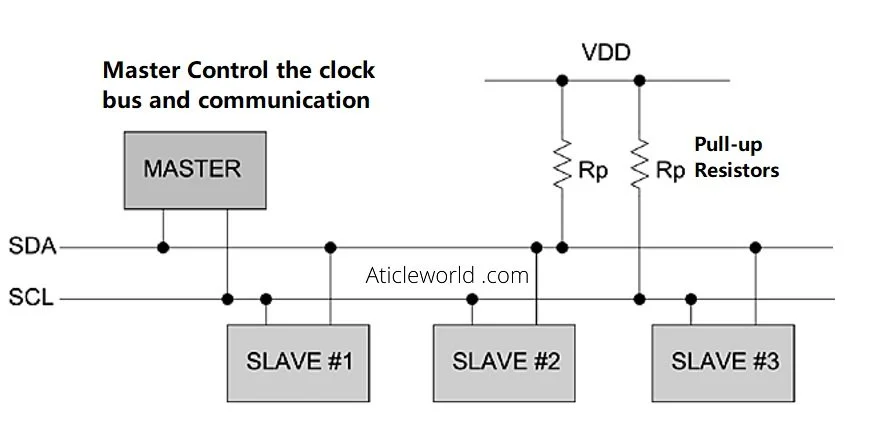

The Bus Master: Multi-device shared busWires: 2 (SDA, SCL) plus power and groundSpeed: 100 kHz (standard), 400 kHz (fast), 1 MHz (fast+)Addressing: 7-bit or 10-bit device addresses

Previous

Previous

Can Raspberry Pi Power Your Next Industrial Prototype?

Next

Next